The industrial sector is continuously evolving, with innovations in automation, material handling, and logistics driving efficiency and productivity. Lorry loading conveyors have long played a crucial role in industries such as mining, construction, agriculture, and logistics, providing efficient, safe, and reliable means of loading materials into trucks. As technology advances, these systems are expected to incorporate new features and capabilities that will further transform industrial loading operations.

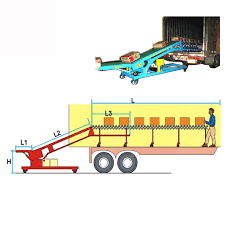

A Lorry Loading Conveyor is designed to transport bulk materials or packaged goods directly into trucks or lorries, reducing manual labor and minimizing spillage. Modern systems already include adjustable height, telescopic sections, and automated controls, enhancing operational efficiency. Looking ahead, businesses exploring Lorry Loading Conveyor solutions can anticipate developments that integrate smart technology, advanced materials, and sustainability features to meet the increasing demands of high-volume and complex industrial operations.

Increased Automation and Smart Controls

One of the most significant future trends in lorry loading conveyors is the integration of advanced automation and smart control systems. These systems will allow conveyors to operate with minimal human intervention, using sensors, AI algorithms, and real-time data analysis to optimize material flow. Future conveyors are expected to automatically adjust belt speed, chute direction, and loading position based on the type of material and vehicle specifications. Smart controls will improve accuracy, reduce spillage, and maximize load efficiency, resulting in faster turnaround times for trucks and higher overall productivity.

Integration with Industry 4.0 Technologies

As Industry 4.0 concepts gain traction, lorry loading conveyors are likely to become part of interconnected industrial ecosystems. This integration includes linking conveyors with warehouse management systems, production schedules, and transport logistics software. Real-time data from conveyor sensors can be analyzed to optimize load sequences, predict maintenance needs, and coordinate with other equipment on site. By connecting conveyors to a broader digital infrastructure, businesses will achieve seamless operations, reduce bottlenecks, and enhance decision-making capabilities.

Advanced Safety Features

Safety will remain a key focus in the development of future lorry loading conveyors. Emerging systems are expected to include enhanced safety mechanisms, such as predictive hazard detection, automated emergency stops, and remote monitoring. Cameras and AI-powered sensors may identify unsafe conditions, including human presence in hazardous zones or material blockages, and automatically halt operations. These improvements will reduce the risk of accidents, protect operators, and ensure compliance with increasingly stringent industrial safety standards.

Improved Energy Efficiency

Sustainability and energy efficiency are becoming central to industrial equipment design. Future lorry loading conveyors are likely to incorporate energy-saving technologies, such as variable frequency drives (VFDs), regenerative braking systems, and intelligent power management. These features will allow conveyors to optimize energy use based on load requirements, operational schedules, and real-time monitoring. Reducing energy consumption not only lowers operational costs but also supports environmental sustainability initiatives, making industrial operations more eco-friendly.

Use of Advanced Materials

Material science advancements will influence the design of future conveyors. High-strength, lightweight, and wear-resistant materials will reduce system weight, improve durability, and decrease maintenance requirements. Abrasion-resistant belts, corrosion-proof rollers, and modular components will extend conveyor lifespan, even in harsh environments. These improvements will allow conveyors to handle a wider range of materials efficiently, from fine powders to heavy aggregates, with minimal downtime.

Mobility and Modular Designs

Future lorry loading conveyors are expected to feature enhanced mobility and modularity. Portable and modular designs will allow operators to reposition conveyors between loading bays or job sites quickly and efficiently. Modular sections may be added or removed to adjust conveyor length, height, or capacity, providing greater operational flexibility. This adaptability will be especially beneficial for industries with varying operational demands or multiple vehicle types, ensuring that conveyors remain a versatile asset.

Predictive Maintenance and AI Analytics

Predictive maintenance is another key area of development. Future conveyors will use AI and sensor data to detect wear, vibration anomalies, and potential component failures before they occur. This proactive approach reduces unplanned downtime, extends equipment life, and lowers maintenance costs. By combining predictive maintenance with performance analytics, operators will be able to optimize loading processes and anticipate operational challenges before they impact productivity.

Conclusion

The future of lorry loading conveyor systems is shaped by automation, smart controls, safety enhancements, energy efficiency, advanced materials, modularity, and predictive maintenance. These innovations will allow industrial operations to achieve higher throughput, reduce labor costs, improve safety, and enhance sustainability. Investing in modern lorry loading conveyors now positions businesses to take advantage of these technological advancements as they evolve, ensuring efficient, reliable, and future-ready material handling solutions across industries.