In today’s competitive manufacturing environment, efficiency, speed, and consistency are essential for meeting market demand. High-capacity water soluble film packaging machines have emerged as a key solution for industries such as detergents, cleaning products, pharmaceuticals, and healthcare. These machines allow the production of large volumes of single-dose packages using water soluble films that dissolve completely in water, providing convenience, hygiene, and sustainability. Scaling production with these machines enables manufacturers to optimize operations while maintaining quality and compliance.

Importance of High-Capacity Packaging Machines

For manufacturers dealing with high-demand products, standard water soluble film packaging machines may not provide sufficient output. High-capacity machines address this challenge by combining advanced automation, multi-lane configurations, and faster operational speeds. This allows for continuous, large-scale production of single-dose units without compromising on quality or consistency.

High-capacity machines also reduce labor requirements by automating feeding, filling, sealing, and cutting processes. This not only improves efficiency but also minimizes human error and contamination risks, which is particularly important for pharmaceuticals, healthcare products, and chemical applications. By integrating a high-capacity system, manufacturers can achieve economies of scale and meet growing market demands effectively.

Key Features of High-Capacity Machines

A high-quality Water Soluble Film Packaging Machine is designed to handle large volumes of products efficiently while maintaining precision and reliability. Multi-lane configurations allow multiple packages to be produced simultaneously, significantly increasing throughput without requiring additional floor space.

Advanced feeding and dosing systems are a critical feature of high-capacity machines. Depending on the type of product—powder, liquid, gel, or granules—the machine can be customized with volumetric pumps, auger fillers, or positive displacement systems. Precise dosing ensures that each single-dose package contains the correct amount of product, maintaining quality standards and compliance with industry regulations.

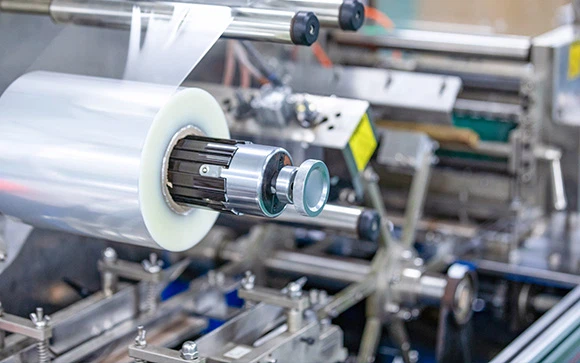

Sealing and cutting mechanisms are also optimized for high-speed production. Heat or ultrasonic sealing systems ensure leak-proof packages, while automated cutting systems maintain consistent dimensions and prevent film waste. Integrated sensors and real-time monitoring allow the machine to detect misaligned packages or irregular fill volumes, automatically adjusting operations to reduce waste and downtime.

Benefits of Scaling Production

Scaling production with high-capacity water soluble film packaging machines offers multiple benefits. First, it enables manufacturers to meet growing consumer demand efficiently. Industries such as laundry detergents and dishwashing pods often require millions of single-dose units, and high-capacity machines allow production to keep pace without compromising quality.

Second, high-capacity machines improve operational efficiency. By automating repetitive tasks, manufacturers can reduce labor costs, minimize errors, and maintain consistent output. Multi-lane machines further enhance productivity by producing several packages simultaneously, maximizing throughput per production cycle.

Third, scaling production improves sustainability. High-capacity machines reduce material waste through precise dosing, accurate sealing, and efficient film utilization. Water soluble films themselves are eco-friendly, dissolving completely in water without leaving residues, making the entire production process more sustainable.

Applications Across Industries

High-capacity water soluble film packaging machines are versatile and suitable for multiple industries. In the detergent and cleaning sector, they produce laundry pods, dishwasher capsules, and single-dose cleaning chemicals efficiently. Large-scale production allows companies to meet seasonal spikes in demand, such as during holidays or promotional periods.

In pharmaceuticals and healthcare, high-capacity machines package powders, gels, and liquids in precise, sterile single-dose units. Hospitals, clinics, and laboratories benefit from the speed and reliability of these machines, ensuring that patient treatments are accurate, hygienic, and readily available. Industrial chemical manufacturers also use high-capacity systems to produce pre-measured doses safely, reducing the risk of overuse and chemical exposure.

Integration with Automation and Control Systems

Modern high-capacity machines come equipped with advanced automation and control systems that support large-scale production. Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) allow operators to set production parameters, monitor performance in real-time, and make adjustments without interrupting the production line.

Automation also facilitates integration with upstream and downstream equipment, such as mixers, conveyors, and packaging trays. This ensures a smooth workflow and consistent production, even at high speeds. Feedback loops and sensor systems help maintain quality control by monitoring fill volumes, seal integrity, and package alignment.

Maintenance and Operational Considerations

To maintain optimal output, high-capacity water soluble film packaging machines require regular maintenance. Cleaning rollers, molds, and sealing components prevents residue buildup and ensures smooth operation. Calibration of dosing systems, inspection of sensors, and monitoring of environmental factors like humidity and temperature are essential, as water soluble films are sensitive to moisture.

Operator training is also critical. Skilled personnel can quickly address issues, make adjustments to machine settings, and conduct preventive maintenance to reduce downtime. Following proper maintenance schedules ensures the machine operates efficiently and reliably over extended production cycles.

Conclusion

High-capacity water soluble film packaging machines offer manufacturers a powerful solution for scaling production efficiently while maintaining quality, hygiene, and sustainability. By leveraging features such as multi-lane configurations, precise dosing systems, automated sealing, and real-time monitoring, manufacturers can meet growing market demands in industries such as detergents, pharmaceuticals, healthcare, and industrial chemicals. Proper maintenance, operator training, and integration with automation systems ensure that high-capacity machines continue to deliver consistent, eco-friendly, and high-volume production, making them indispensable for modern industrial packaging.